In addition, the effect of undercut to the root fillet geometry is discussed. It also shows pinion root fillet geometry generated by cutter tip fillet profile only.

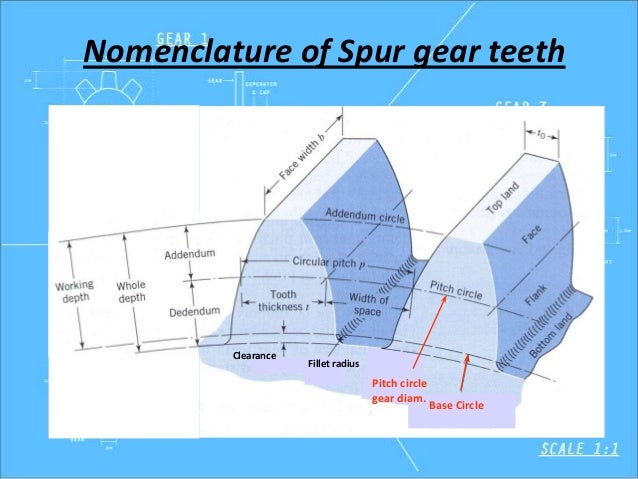

This paper shows examples that pinion root fillet geometry generated by both TOPREM and cutter tip fillet profile. The Gleason pinion cutters consist of three parts: main profile, TOPREM, and cutter tip fillet profile. For the more complicated spiral bevel and hypoid gears, the root fillet geometry by Gleason modified roll method is discussed. coefficient of fillet radius of the rack cutter, R/m. The phenomenon of undercut is discussed as well. Figure 3 represents the rack cutter used to generate the gear. For spur and helical gears, the root fillet geometry cut by a rack with and without cutter tip radius is discussed. The gear root fillet equations are derived based on the simulation of cutting tool motion on the gear blank during the manufacturing process. In general, spur gear with less than 17 numbers of teeth had the problem of undercutting during gear manufacturing process which minimizes the strength of gear at root. Corrective measures are taken to avoid tooth damage by introducing profile modification in root fillet. Since a good knowledge of the gear root geometry is required to calculate bending stress, the purpose of this paper is to present the root fillet geometry of spur, helical, spiral bevel, and hypoid gears. This paper examines the tooth failure in spur gears. However, it is still difficult to apply to gears due to very complicated geometry, especially in the root fillet area. The finite element method has been successfully applied to the analysis and design of components and structures of a vehicle. As modern vehicular applications demand higher power density gears, accurate analytical tools to predict gear stress are required.

0 kommentar(er)

0 kommentar(er)